Simulation Glass Pressing

The simulation of glass pressing can easily be performed with our CFD software NOGRID points. A large number of products is produced using the glass pressing process: Lenses, dishes, asher, drinking glasses, boals, sinks, bottles, and containers (press and blow process).

The market constantly demands thinner container walls, lighter objects and better textures making glass production far more complex than the apparent commonality of the produced goods.

The meshless CFD software by NOGRID has been used successfully for the improvement of the glass pressing process for many years. The combination of free surface deformation under the combined effect of

- the motion of different solid devices (molds, plunger, etc.),

- gravity,

- the cooling process (mainly due to the heat exchange with the mold and the plunger),

- the mechanical and thermal detection of the contact between the deforming glass and the moving parts

create a better understanding of the mechanism of the glass pressing process. This better understanding quickly leads to tremendous savings in manufacturing costs and time while ensuring a final product of high quality.

Glass pressing is probably the application where the deformations are largest. In figure 4, the process begins with a sample of glass that is a sphere. During the pressing process, the solver automatically refines the point cloud where this is necessary. Refinement may appear where very large deformations occur or where the geometrical details of the mold require them. Intelligent algorithms automatically refine the grid only where and when this is necessary during the run both in 2D and in 3D. These techniques are especially important when small geometrical details are involved in the final product.

The pressing of glass is limited by two major effects. If the pressing time is long, the cold mold or cold plunger can freeze the flow or generate chill ripples at the glass surface. On the other side, when the pressing time is short, the plunger velocity is very high. In that case the glass could tear apart.

Our software is able to predict such effects and helps designers to find the right geometry for their molds and plungers. Beside the normal flow with Newton's viscous law NOGRID points is also able to run the computation with non-Newtonian materials (also viscoelastic material behavior is included).

- computation is in full 3D solving complete Navier-Stokes-Equations

- easy and intuitive setup of the FSI (Fluid-Structure-Interaction) case

- free definable material properties by equations or curves

- moving parts with a lot of moving features

- open or closed domains including moving of additional parts

- including temperature computation of the solid molds

Follow this link to learn more about how simulation can help with the design of pressed glass.

Nogrid's strengths

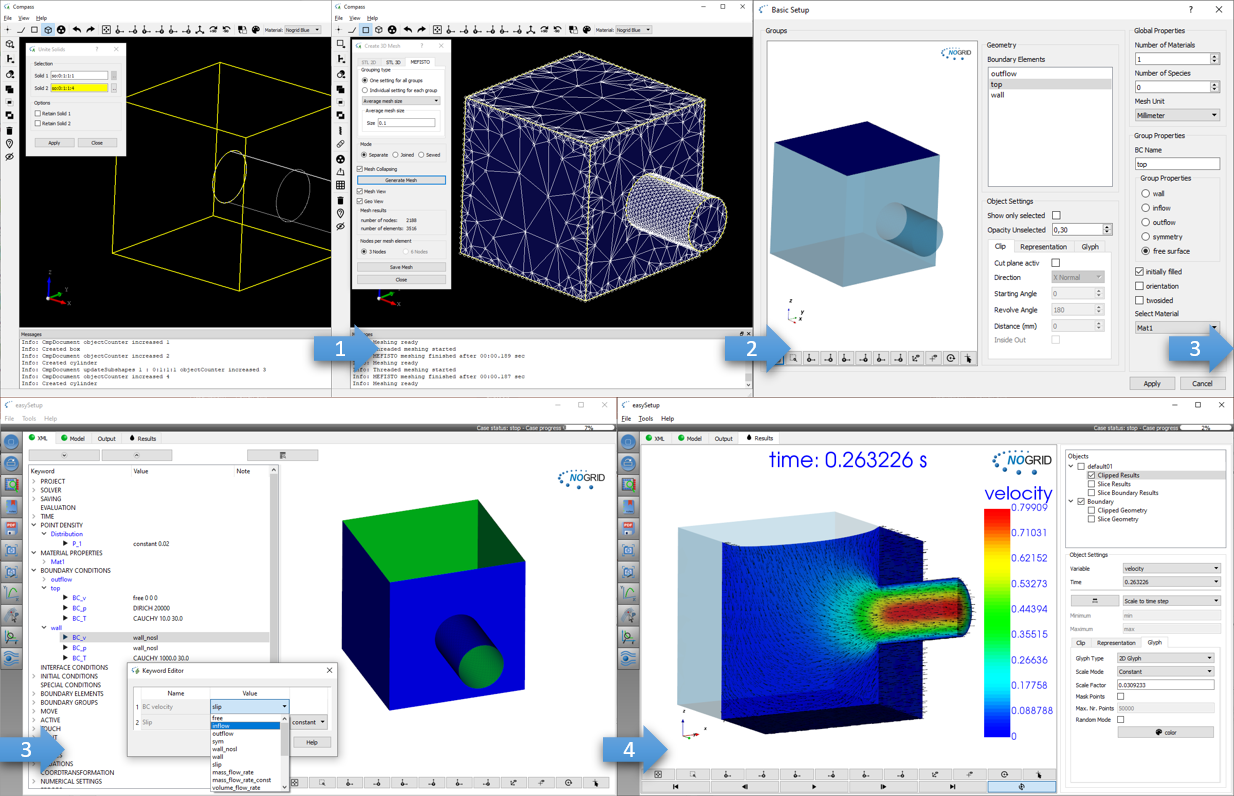

Easy and fast modelling: Build geometry, mesh boundary, setup the case and start computation

What is CFD from NOGRID?

CFD solves the fundamental equations that define the fluid flow process. With CFD software from NOGRID every engineer makes better decisions by predicting, analyzing and controlling fluid flow, heat and mass transfer or chemical reaction. By using NOGRID software for flow modeling you receive information on essential flow characteristics as for example flow distribution. Using it additional to testing and experimentation NOGRID software helps to improve the evaluation of your design – resulting in better construction and operation parameters, increasing planning security and money savings due to faster time to the marketplace for your product or process.

Choose NOGRID

With NOGRID, you choose professional CFD software and services – our aim is helping you to be successful. When you decide to work with NOGRID you choose close cooperation with a dynamic, flat hierarchies-organization. Short information channels result in quick and accurate professional support and service. Our team consists of highly qualified employees, who are experts in fields such as numerical simulation or computational fluid dynamics. Based on our know-how, we are pleased to offer the following services, responding to your individual requirements:

TRAINING

In our two-days training courses you will learn, how to use NOGRID CFD software efficiently. Our technical support team will teach you how to handle and solve different cases.

For more details please refer to Training Courses →

Technical Support

We offer full professional support from the minute you start using our software, by telephone or by email. Contact us, when ever needed.

For more details please refer to Software Support →

Service

Lack of time or resources and other constraints often make outsourcing an attractive solution. We help you with your flow modeling needs. Based on our engineering expertise in this field we offer individual numerical simulation services matching the unique needs of your organization.

For more details please refer to Simulation Services →